INFRASTUCTURE

- Home

- Infrastucture

INFRASTRUCTURE

Group’s Foundry facilities are spread over in 06 different plants with 04 locations across India. All plants are well equipped with the latest Moulding Technologies like DISA make High-Pressure Lines with Flask & without Flask, High Productive, Robotic Venting Systems, etc. Molding lines are supported by DISA make Auto Controlled Sand Plants with effective Sand cooling, Handling systems & High-Speed Intensive Mixers with different capacities. Sand Mix Controls (SMCs) are ensuring the delivery of good quality Sand with Auto Process Control & Testing Facilities.

MELTING FACILITY

Group is having a capacity of melting 20 tons of metal per hour from its technologically upgraded Melting sections. Melting sections are equipped with Inductotherm to make Dual, Tri & Quadra Track Medium Frequency Furnaces with different pot capacities, Auto Raw material charging & alloy addition systems with the help of high-speed magnetic lifter & Vibro-charger, etc.

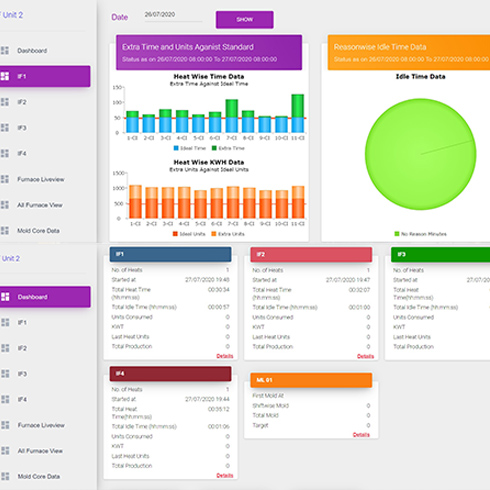

INDUSTRY 4.0 (IT)

Great innovations by our in-house IT Team, i-Melt & Energy Management system (EMS) are helping us to track real-time data of KW, KWH, Time for every heat and significantly controlling Unit Consumption and Heat Time.

AUTO POURING SYSTEM

Pouring Sections are also adding great value by pouring required metal well in time with help of Kunkel Wagener Fully Auto Lift Pouring System which operates with a press of a single button, Inductotherm makes Auto Pour & ABP make Press pour systems. Steam inoculation & Quick ladle change system enables us to maintain good casting quality with high productivity.

MOUDING FACILITY

DISA makes modern box & casting handling system, Knock Out, Casting Cooling conveyor, Slat conveyors are capable to prevent Castings from handling damages for weight range from 1 Kgs. up to 400 Kgs.

ROBOTIC FETLLING

Fettling shops equipped with DISA make Shot Blasting machines, sophisticated MAUS Robotic Grinding machines, Grind-master make Robotic Machines, and Trimming & Snag Grinding Machines helped us to remove Foundry bottlenecks by maintaining expected Quality & productive.

Melting Centre

SHRIRAM FOUNDRY PVT. LTD. - KOLHAPUR (1984)

Inductotherm MF Furnaces.

750 Kgs./ 750 KW - Dual track,750 Kgs./750 KW - Dual track

500 Kgs./500 Kw - Mono Track, Melting - 2000 Tons/mont

Real time Production and Unit consumption data monitoring through i-Melt & EMS

ASHTA LINERS PVT. LTD. - ASHTA (HPML) (1989)

Inductotherm MF Furnaces.

3 Pots of 1500 Kgs. each with 2250 KW - Tri track

Melting – 1800 Tons/month

Real time Production and Unit consumption data monitoring through i-Melt & EMS

S. J. IRON & STEELS PVT. LTD. - KOLHAPUR (2005)

Inductotherm MF Furnaces.

1000 Kgs. 1000 KW - Dual track , Melting - 800 Tons/month

Real time Production and Unit consumption data monitoring through i-Melt & EMS

KASTURI FOUNDRY PVT. LTD. - ASHTA (2007)

Inductotherm MF Furnaces.

3 Pots of 1000 Kgs. each with 2250 KW - Tri track

Melting - 1800 Tons/month

Real time Production and Unit consumption data monitoring through i-Melt & EMS

SHRIRAM FOUNDRY PVT. LTD. - PANTNAGAR (HPML) (2008)

Inductotherm MF Furnaces.

3 Pots of 1500 Kgs. each with 2250 KW - Tri track

Melting – 2200 Tons/month

Real time Production and Unit consumption data monitoring through i-Melt & EMS

KASTURI FOUNDRY PVT. LTD. - KAGAL (HPML) (2018)

Inductotherm MF Furnaces.

Inductotherm MF Furnaces.

4 Pots of 1500 Kgs. each with 4000 KW - Quard track Melting,

Melting - 800 Tons/month - 6 Tons/Hr. & 4000 Tons/month, High-speed magnet lifter with Vibro charger, Non-contact lesser temperature pyrometers

Real time Production and Unit consumption data monitoring through i-Melt & EMS

Molding Line

SHRIRAM FOUNDRY PVT. LTD. - KOLHAPUR (1984)

DISA Flask less HPML line – 700 X 600 X 300 mm

Mold Production – 120 /Hr

ARPA 900, Horizontal Parting : 800 x 700 x 350 mm

No Bake Molding – 2000 x 1200 x 300 mm

ASHTA LINERS PVT. LTD. - ASHTA (HPML) (1989)

DISA Flask less HPML line – 700 X 600 X 250 mm

Mold Production – 100 /Hr

ARPA 900, Horizontal Parting : 800 x 700 x 350 mm

No Bake Molding – 2000 x 1200 x 300 mm

S. J. IRON & STEELS PVT. LTD. - KOLHAPUR (2005)

ARPA 900, Horizontal Parting : 750 x 650 x 350 mm

ARPA 450, Horizontal Parting : 700 X 500 X 200 mm

Shell Molding

KASTURI FOUNDRY PVT. LTD. - ASHTA (2007)

ARPA 1300, Horizontal Parting : 1100 x 900 x 350 mm

ARPA 900, Horizontal Parting : 800 x 700 x 350 mm

SHRIRAM FOUNDRY PVT. LTD. - PANTNAGAR (HPML) (2008)

DISA HPML Flex70 – 900 X 700 X 325 mm

Mold Production – 80 Molds /Hr

ARPA 450, Horizontal Parting : 750 x 650 x 250 mm

KASTURI FOUNDRY PVT. LTD. - KAGAL (HPML) (2018)

DISA HPML Flex70 – 1000 X 700 X 350 mm

Mold Production – 100 Molds /Hr

Robotic venting system

Auto core Assembly Transfer Fixture

Sand Plant

SHRIRAM FOUNDRY PVT. LTD. - KOLHAPUR (1984)

DISA TM 160 High Speed Intensive Mixer

Automated Sand Plant

Sand Cooling System

Auto Sand Mix Control (SMC)

ASHTA LINERS PVT. LTD. - ASHTA (HPML) (1989)

DISA TM 190 High Speed Intensive Mixer

Automated Sand Plant

Sand Cooling System

Auto Sand Mix Control (SMC/GSC)

S. J. IRON & STEELS PVT. LTD. - KOLHAPUR (2005)

Automated Sand Plant

DISA High Speed Intensive Mixer TM-160

Sand Cooling System, Wesman

KASTURI FOUNDRY PVT. LTD. - ASHTA (2007)

DISA TM 190 High Speed Intensive Mixer-2 Nos

Automated Sand Plant

Sand Cooling System

SHRIRAM FOUNDRY PVT. LTD. - PANTNAGAR (HPML) (2008)

DISA TM 240 /160 High Speed Intensive Mixer

Automated Sand Plant

Sand Cooling System

Auto Sand Mix Control (SMC)

KASTURI FOUNDRY PVT. LTD. - KAGAL (HPML) (2018)

DISA TM 285 High Speed Intensive Mixer

3.2 Tons batch, 100 Tons/Hr

Automated Sand Plant with Cooling System

Auto Sand Mix Control (SMC)

400 Tons sand storage capacity

Surface Coating

Modern Surface coating facilities are adding more value in Zanvar Group Ferrous casting Business. Group is having a separate division with advanced Cathode Electro Deposition (CED) Coating, Liquid Nitriding & Powder coating plants. CED & Powder coatings give protection life of 500-1000 Hrs. for salt spray & Humidity. Nitriding is improves surface hardness up to 450 HV & enhancing wear resistance. Apart from this dedicated facility all Foundries are supported by Conveyorised paint shops with Paint baking Oven facilities.

LIQUID PAINTING

Electrostatic Spray Painting two stations

100 Mtrs. Conveyor system

Auto control Paint Baking Oven

ETP

CED COATING

Uniform coating

Better corrosion protection up to 500 Hrs

Better humidity protection up to 500 Hrs.

NITRIDING & POWDER COATING

Improves surface hardness to 450 HV

Enhance wear resistance

Corrosion protection up to 500 Hrs.

Improves aesthetics

Machining Division

Modern & advance machining division to provide a World Class finished good castings to our customers.

HORIZONTAL MACHINING CENTERS

QTY. :- 350

SPECIAL PURPOSE MACHINES

QTY. :- 450

TURNING CENTERS

QTY. :- 175

VERTICAL MACHINING CENTERS

QTY. :- 275

CNC/CMM

QTY. :- 11

Technology Up-gradation

Group Foundry infrastructure is supported by technically advanced inspection & test facilities like, Bosello make Online X-Ray Testing for checking internal soundness of castings, GOM Germany make Casting Scanning machine for easy & fast Dimensional Inspection, ‘Any Cast’ Casting simulation for first time right development, modern Magnetic Particle Inspection facilities etc. Additionally all foundries are backed with well-equipped Metallurgical Testing Labs, Spectrometers, Universal Testing Machines, Micro-structure with image analysers, Harness testing etc.

BOSELLO ITALY MAKE

Online casting X-ray testing

CASTING SIMULATION

Casting simulation software to improve yield

of casting

GOM GERMANY MAKE

Casting inspection scanner

SPECTROMETER

Metallurgical inspection at all foundries

3 COORDINATE MEASURING MACHINE

Available at all machining locations